On June 7, 2020, the China Petroleum and Chemical Industry Federation organized relevant experts to hold a scientific and technological achievement appraisal meeting on "Low Water/Gas (CO) Ratio Organic Sulfur Conversion Type Sulfur-Resistant Shift Catalyst" in Qingdao. The appraisal committee believes that: this technology has independent intellectual property rights, advanced technical indicators, obvious energy-saving and emission reduction effects, strong applicability and innovation, and the overall technology is at the international leading level.

1. Importance of project development

The production process of coal chemical industry mainly consists of three parts: coal gasification, conversion purification and synthesis. CO shift technology is an important technology that uses the excess CO produced by gasification in the coal chemical production process to undergo a shift reaction with H2O (water vapor) under the action of a catalyst to produce H2. Since this process consumes a large amount of water steam, the use of a new low water/gas (CO) ratio sulfur-tolerant transformation process can significantly reduce steam consumption and the amount of discharged condensate, and the energy saving effect is significant.

However, with the development of new coal chemical technology and the development and use of inferior high-sulfur coal, it was discovered that when the content of H2S and other components in the raw gas is high and the water/gas content is low, not only the organic sulfur conversion rate will be affected by the chemical balance, but If the reaction temperature decreases, new sulfide by-products such as mercaptans and thioethers will be generated; and the generation of sulfides such as mercaptans is closely related to the reaction temperature. The lower the temperature, the more conducive to the generation of thiols. Industrial unit operation data also shows that trace amounts of substances such as methyl mercaptan are detected at the outlet of the low-variability reactor of some industrial units. Not only does it affect the promotion and use of energy-saving low water-gas ratio conversion technology, but also because mercaptan sulfides are generated under low temperature conditions, it affects the development and application of isothermal conversion technology, which has become a problem that currently plagues and restricts coal chemical production and needs to be solved urgently. important issues.

In response to new problems arising from the conversion process: Qingdao Lianxin Catalytic Materials Co., Ltd., Shanxi Lu'an Coal-based Clean Energy Co., Ltd., China University of Petroleum (Beijing) and Yunnan Shuifu Yuntianhua Co., Ltd. are working together to save energy and reduce consumption. Developed a low water/gas (CO) ratio organic sulfur conversion type sulfur-tolerant shift catalyst to solve the problem of high CO and high sulfur coal raw gas easily generating methyl mercaptan and thioether under low water/gas (CO) ratio and low temperature conditions. The technical difficulties of organic sulfur-containing compounds have ensured the implementation of new transformation processes such as energy-saving low water/gas (CO) ratio, broadened the selection range of raw coal, and promoted energy conservation and consumption reduction in the coal chemical industry.

2. Industrial sideline and industrial application

The catalyst completed laboratory research in December 2015. In April 2016, a one-month industrial sideline experiment was carried out in the ShelL pulverized coal gasification low-water gas sulfur-resistant shift methanol production unit (300,000 tons/year) of Yunnan Shuifu Yuntianhua. The test was compared with the low water/gas (CO) ratio QDB-05 catalyst in use. The results showed that the newly developed catalyst has the same performance as the QDB-05 catalyst in terms of conversion activity and resistance to methanogenic side reactions, but the production of by-products such as methyl mercaptan is significantly lower than that of the QDB-05 catalyst.

In October 2017, the catalyst was industrially applied in the second shift furnace of the million-ton coal-to-liquids unit in Lu'an, Shanxi. Industrial data show that the developed QDB-07 catalyst has good conversion activity, small bed pressure difference, and stable operation; during the period of operation of the unit with high sulfur coal for several months, no mercaptan and sulfide by-products were detected at the outlet of the conversion unit, and the subsequent process was not affected by by-products such as mercaptan, indicating that the QDB-07 catalyst not only has excellent low-temperature activity and activity stability, but also has good organic sulfur conversion activity and the function of reducing the generation of methyl mercaptan organic sulfur by-products, ensuring the implementation of new energy-saving conversion technologies such as low water-gas ratio in my country, significantly reducing the use of steam, and achieving significant economic benefits. Taking the 1.8 million tons/year coal-to-liquid conversion unit in Lu'an, Shanxi as an example, the annual economic benefit of the conversion unit saving steam is 404 million yuan.

3. Prospects for promotion and application

my country is the world's largest coal producer. The production of ammonia, methanol and city gas using coal as raw materials occupies an important position in my country's chemical industry. Among coal resources, the output of inferior high-sulfur coal accounts for about one-third of the total coal reserves. Therefore, the development and utilization of high-sulfur coal is an important topic of recent research and attention. At present, the gasification technology of high-sulfur coal has been conquered, and large-scale coal chemical plants have been designed or under construction. If a high water-gas ratio conversion process is used, it is bound to repeat the mistakes of a large amount of energy waste in the high water-gas ratio conversion process. If a low water-gas ratio conversion energy-saving process is used, the production of mercaptan by-products will cause difficulties in the subsequent purification process. If an isothermal conversion process is used, the problem of methyl mercaptan by-products will be more serious due to the low isothermal conversion temperature and the fact that methyl mercaptan is easily formed at low temperatures. The production of the generated mercaptan by-products will cause difficulties in the subsequent purification process.

The successful development of QDB-07 organic sulfur conversion catalyst makes it possible to implement high-sulfur coal raw gas under low water-gas ratio conversion process, filling the international gap in the application of pulverized coal gasification high CO and H2S raw gas under low water-gas ratio process conditions. It not only meets the needs of energy conservation and consumption reduction of my country's coal chemical technology, but also broadens the selection range of coal chemical raw materials. It is an important way and strategic measure to ensure the safe supply of raw materials for coal chemical production and practice energy conservation, consumption reduction and emission reduction. It has important practical significance for the technological progress, expansion and transformation, energy conservation and consumption reduction, and rational and full use of resources of my country's modern coal chemical industry, and has a very broad prospect for promotion and application.

Block diagram or section introduction

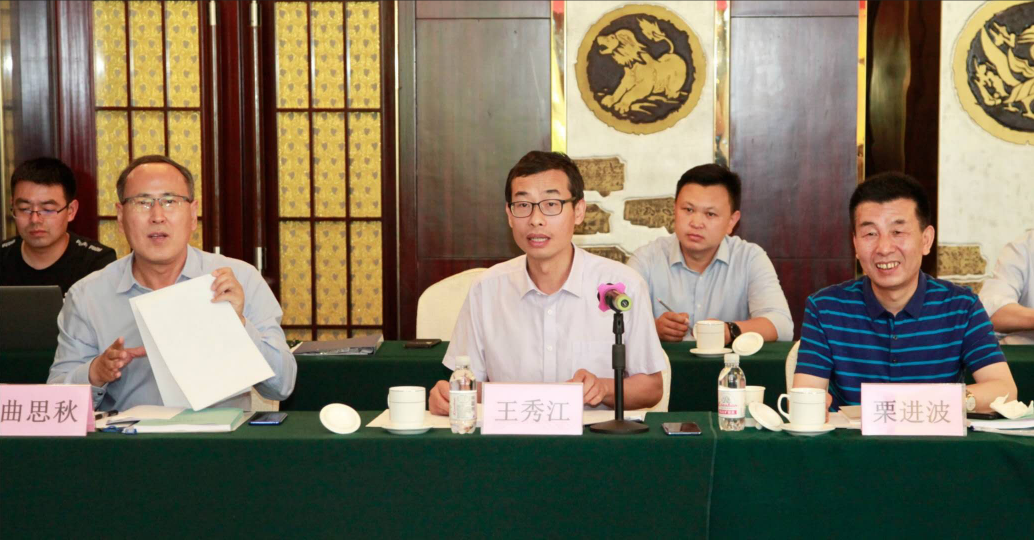

The appraisal meeting was chaired by Wang Xiujiang, deputy director of the Science and Equipment Department of the China Petroleum and Chemical Industry Federation. The appraisal committee was chaired by Gu Zongqin, chairman of the China Nitrogen Fertilizer Industry Association, Lu Zhengtao, chief technical expert of Aerospace Long March Chemical Engineering Co., Ltd., and Jing Hongjian, professor-level senior engineer of Shanxi Tianji Coal Chemical Group Co., Ltd., as vice chairmen, Li Shaolei, chief technical expert of Wanhua Chemical Group Co., Ltd., Wang Guangjian, professor of Qingdao University of Science and Technology, Zhang Kongyuan, professor of China University of Petroleum (East China), Xie Feidong, deputy general manager of Henan Energy and Chemical New Materials Co., Ltd., and Huang Xiufeng, deputy general manager of Shandong UBS Biochemical Co., Ltd., as members of the appraisal committee.

Zong Qiuyun, deputy general manager of Qingdao Lianxin Catalytic Materials Co., Ltd., and Liu Wenlin, chief engineer of Shanxi Lu'an Coal-based Clean Energy Co., Ltd., respectively reported on catalyst research and development, industrial side-line tests, and industrial applications, and accepted and answered on-site questions from experts.

Li Jinbo, chairman of Shanxi Lu'an Coal-based Clean Energy Co., Ltd., Qu Siqiu, chairman of Qingdao Lianxin Catalytic Materials Co., Ltd., and Li Qinggang, general manager, attended the meeting.